ALEX® IEC Standard Steel EMT Fittings (Couplings & Connectors)

STEEL

(Spanish Reference: CONECTORES Y COPLAS DE ACERO PARA TUBERÍA EMT)

Product Definition

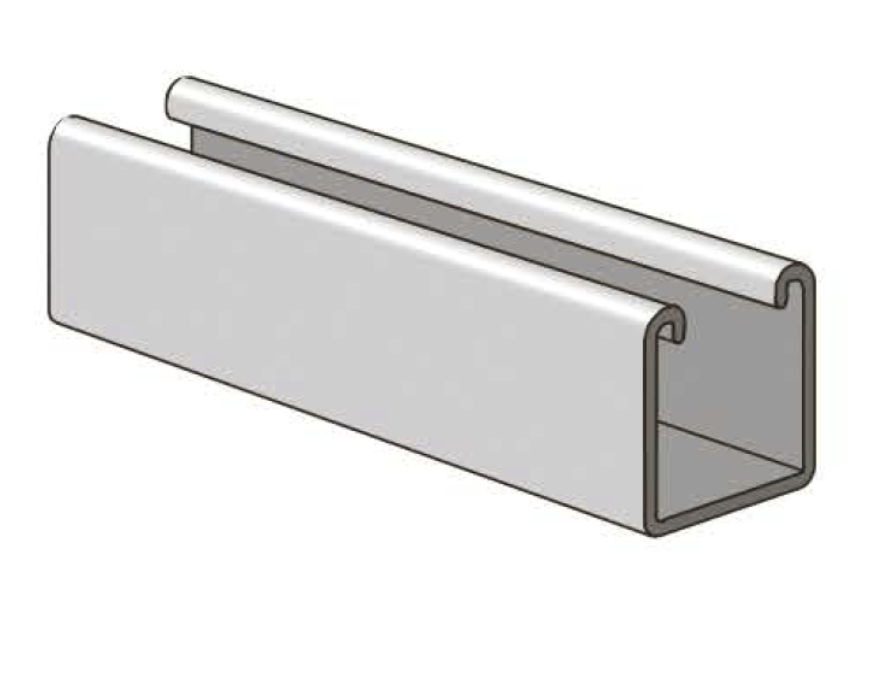

ALEX® Steel EMT Fittings are the premium choice for electrical installations requiring superior mechanical strength and structural integrity. Unlike standard zinc die-cast fittings, these couplings and connectors are manufactured from high-grade tubular steel, making them virtually unbreakable under normal job site conditions.

Designed strictly according to IEC 61386 standards, they provide a secure, impact-resistant connection for EMT conduits in commercial and industrial environments where durability is prioritized over basic corrosion resistance.

Material Comparison: Why Choose Steel?

While Zinc Die-Cast is popular for general use, Steel is the superior choice for demanding indoor applications.

| Feature | ALEX® Steel Fittings | Zinc Die-Cast Fittings |

| Material Strength | High (Resists crushing & impact) | Moderate (Can crack under heavy stress) |

| Impact Resistance | Excellent (Ideal for exposed areas) | Low (Brittle upon hard impact) |

| Profile | Slim & Compact (Tubular design) | Bulky (Cast design) |

| Primary Application | Industrial / High-Traffic Areas | General Residential / Light Commercial |

| Cost | Premium Performance | Economical Standard |

Product Variants & Specifications

We offer the full range of Steel EMT fittings to suit your installation needs:

1. Steel EMT Connector (Set Screw Type)

Function: Joins EMT conduit to a junction box or enclosure.

Features: Pre-installed steel locknut, heavy-duty set screw for reliable grounding.

2. Steel EMT Coupling (Set Screw Type)

Function: Joins two lengths of EMT conduit together.

Features: Concrete-tight when taped, withstands heavy mechanical pull-out forces.

Size Chart (IEC Metric)

| Metric Size (mm) | Conduit Compatibility | Material |

| 20 mm | IEC 20mm EMT | Tubular Steel |

| 25 mm | IEC 25mm EMT | Tubular Steel |

| 32 mm | IEC 32mm EMT | Tubular Steel |

| 40 mm | IEC 40mm EMT | Tubular Steel |

| 50 mm | IEC 50mm EMT | Tubular Steel |

| 63 mm - 110 mm | IEC Large Sizes | Tubular Steel |

Key Features

Superior Durability: Capable of withstanding accidental hits from tools or equipment without cracking.

Space Efficient: The thin-wall steel construction offers a lower profile than bulky die-cast fittings, ideal for tight conduit racking.

Secure Grip: Hardened steel screws bite deeply into the conduit, ensuring excellent ground continuity.

Compliance: Meets international electrical safety codes (IEC 61386).

Frequently Asked Questions (FAQ)

Q: When should I use Steel instead of Zinc fittings?

A: Use Steel when the conduit runs are exposed to potential physical damage (e.g., warehouses, loading docks, exposed ceilings) or when you need the highest possible mechanical security. Use Zinc for standard concealed wall installations where cost is the primary factor.

Q: Are these fittings rust-proof?

A: Our steel fittings are Electro-Galvanized (Zinc Plated) to provide corrosion resistance suitable for indoor dry locations. For wet or corrosive outdoor environments, we recommend our specialized Liquid Tight or Hot-Dip Galvanized Rigid fittings.

Q: Do steel fittings fit standard IEC conduit?

A: Yes. They are precision-manufactured to fit all standard IEC 61386 metric EMT conduits (20mm to 110mm).

Q: Do you offer OEM branding?

A: Yes. We support OEM production. We can customize packaging (bags/boxes) and labeling to match your brand requirements.

Q: What is the lead time?

A: Our standard lead time is approximately 4 weeks. We recommend confirming specific delivery schedules with our sales team before placing large orders.

RELATED PRODUCTS:

EMT CONNECTORS-ZINC DIE CAST IEC STANDARD,

EMT COUPLINGS - ZINC DIE CAST IEC STANDARD.